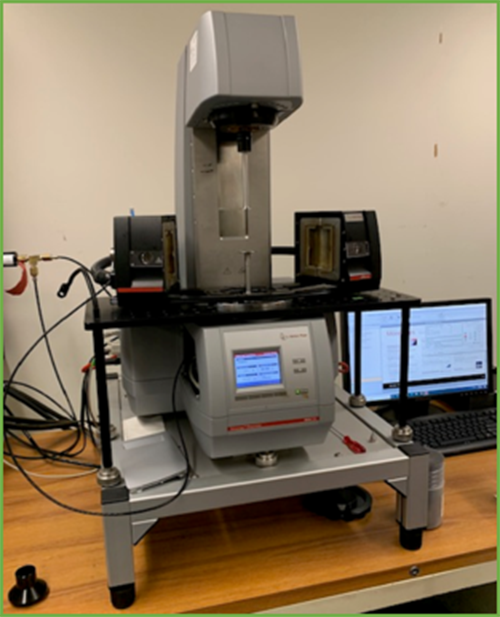

TA INSTRUMENTS AR-G2

Anton Paar Rheometer

Summary of Technique

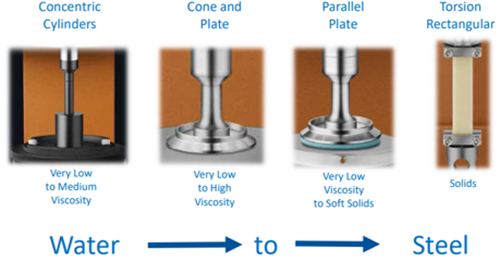

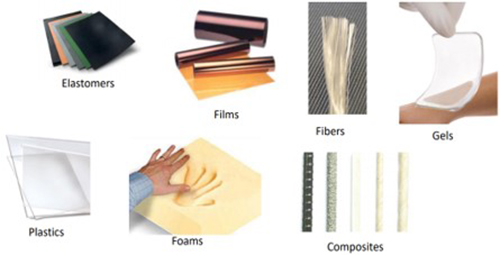

Rheometer measures both viscosity and viscoelasticity of fluids, semi-solids and solids. In a rheological measurement stress, strain (shear rate) are all calculated signals. The raw signals behind the scene are torque, angular displacement and angular velocity.

- Viscosity- defined as a materials resistance to deformation and as a function of shear rate or stress with time and temperature dependence.

- Viscoelasticity- is a property of a material that exhibits both viscous and elastic character.

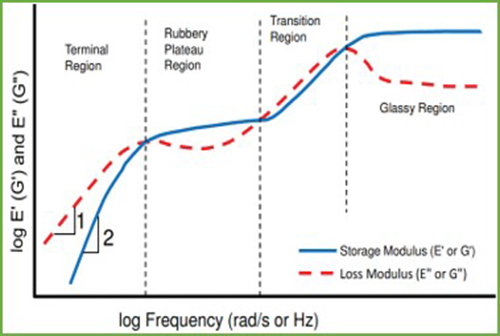

Common testing methods are:

- Stress and strain sweep

- Time sweep

- Frequency sweep

- Temperature ramp

- Temperature sweep

- Stress relaxation

Information Provided

- Los modulus, storage modulus, tan delta with respect to time, temperature, frequency and stress/strain

- Yield stress

- Non-Newtonian viscous behavior

- Thixotropy

- Elasticity

- Stress relaxation

- Viscosity

- Curing rates

- Flow behaviors

- Crosslinking density

- Stability of materials

Lab Location and Contact Information

Location: Thermal Analysis, Rheology, and Polymer Processing Lab

Point of Contact: Dennis Ndaya

dennis.ndaya@uconn.edu

860-486-4075